|

| December 01, 2015 | Volume 11 Issue 45 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Identify the right surface finish for injection-molded parts

By Gus Breiland, Customer Service Engineering Manager, Proto Labs

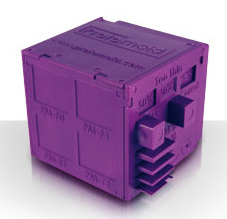

The Protomold sample folding cube design tool demonstrates available surface finishes and other important design considerations, including bosses, gussets, through holes, ribs, undercuts, and more.

Molded parts are everywhere -- from highly cosmetic housings hiding in plain sight to internal components where a fine polish is unnecessary. Most people pay no attention to the surface finish on those parts, but for product designers and engineers, it's an important design consideration.

Identifying the right surface finish is dependent on a few important elements, namely the development or production stage that your parts are in, the materials they're being manufactured in, and their end-use applications.

Plastic finishes

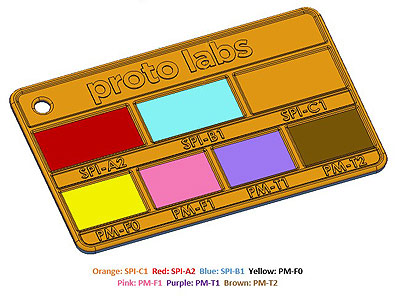

Injection molding offers hundreds of thermoplastic resins that are flexible, strong, and can have fine cosmetic finishes. At Proto Labs, aluminum molds can be quickly produced by three-axis milling and easily hand polished or textured to one of seven surface finishes, which range from non-cosmetic to high-gloss polish:

- PM-F0: Non-cosmetic, finish to Proto Labs discretion

- PM-F1: Low-cosmetic, most toolmarks removed

- SPI-C1: 600 grit stone

- SPI-B1: 600 grit paper

- SPI-A2: Grade #2 Diamond Buff

- PM-T1: Light bead blast

- PM-T2: Medium bead blast

All polish and texture is applied directly to the mold itself and transferred to the parts during the injection molding process. For this reason, secondary finishing is not available, which makes material selection critical in some cases. Typically, the link between the surface finish and material is small, but glass, mineral, or soft and high-shrink materials can produce parts that don't always reflect what you may be looking for in a finish.

Glass- and mineral-filled materials provide unique material properties that unfilled materials don't, but be cautious when using them if they are intended to be a highly cosmetic part. Glass and minerals can create material streaking, and the polish can even be difficult to distinguish between grades. This isn't the case with all filled resins, but we suggest speaking with one of our customer service engineers (CSEs) or requesting a material sample plaque of the actual material you intend to use.

At Proto Labs, you'll receive a fully interactive quote with design for manufacturability (DFM) feedback that highlights problematic areas where increased attention should be paid -- a textured surface may have more draft requirements than a polished surface would, for instance.

Draft is required for two reasons: to provide proper release from the mold so you can avoid scratches or drag marks on your part and to provide a proper angle for a bead-blast finish to be applied to the mold. A minimum of 3 degrees draft is required for a PM-T1 finish and a minimum of 5 degrees for a PM-T2. Additionally, finishes on deep and thin ribs may not be possible on parts, as they are challenging to reach within the mold.

In addition to the seven available surface finishes at Proto Labs, you can also obtain a custom finish. With a custom finish, you still have to choose from the seven options, but different finishes can be applied to the A and B sides of the mold. Note that the A side of the mold typically represents the outside of the part, and the B side is often the one with the most retention and ejector pins.

We can easily add a custom finish as long as you follow these simple rules:

- Provide a clearly marked, color-coded image (jpg or pdf) of your part indicating the finishes required.

- The part has clearly defined surfaces with a minimum of 0.015 in. of feature height definition, so we can mask off areas for polish or texturing.

- A CAD model is provided with the aforementioned required draft angles for the chosen textures.

On custom finishes, use color coding to provide a clearly marked image of your CAD model with its required finishes.

Gating and part ejection on clear or cosmetic parts is another consideration to keep in mind. If you have a clear lens, or if the side with the most retention is actually the cosmetic side of the part, you may want to have a discussion with one of our customer service engineers (CSEs). Ejector pins vary in size, location, and quantity but are oftentimes a necessity for extracting a part from the mold.

Alternatives may be possible, so contact a CSE at customerservice@protolabs.com or at 877.479.3680 with any questions you may have.

LSR finishes

Liquid silicone rubber (LSR) is a thermoset material using the same manufacturing methods for producing a mold as earlier discussed, but the molding process itself is different. LSR molding uses two liquids mixed together, which are then heat cured in the mold to produce a final part.

Surface finish options for LSR are nearly identical to that of thermoplastics.

Surface finish options for LSR are the same as plastic finishes minus the SPI-B1 finish. And like plastic, a custom option that may include two or more of the available finishes is also possible. Unlike plastics, however, LSR is much more forgiving as no ejectors are required for the removal of the parts. All LSR parts are manually pulled from the mold, so you don't need to consider ejection or retention using this process. Another bonus is gating, LSR has extremely shallow gates that are nearly undetectable after molding.

Metal finishes

Metal injection molding (MIM) is a fabrication method used for low-volume steel and stainless steel parts (typically, 5,000+ parts) and works as the next step after CNC machining or 3D printing with direct metal laser sintering (DMLS). MIM uses the same technology as plastic and LSR molding to produce a mold, but instead of injecting plastic, a metal powder bound together by a catalyst is molded, debinded, and finally sintered to create a fully dense (typically 97 percent) part.

MIM finishes are applied to the mold by hand polishing, the same as it would for thermoplastics. But due to the multistep process, MIM supports only SPI-C1 and SPI-B1 surface finishes. The reason we only offer those two finishes is because a higher level of polish (minimum of C1) is needed, so the parts don't stick in the mold -- MIM feedstock is more "sticky" than plastics. Anything above a B1 finish will not translate into a better surface finish on the part due to this multistep process.

On MIM parts, SPI-C1 and SPI-B1 surface finishes are offered.

Magnesium injection molding (aka thixomolding) is a process for molding fully dense magnesium parts, similar to those produced in die casting or CNC machining. The process of injection molding magnesium involves heating chipped magnesium into a thixotropic slurry and forcing it into the mold similar to that of plastic injection molding. Magnesium injection molding provides a part surface finish that would be comparable to those of zinc die-cast parts. Proto Labs finishes the molds using an SPI-C1 polish, as higher finishes in the mold would not produce a higher cosmetic part.

Magnesium parts typically require post-processing to improve cosmetics, durability, and other attributes.

Magnesium oxidizes, so in many applications some type of post-processing finishing should be applied. Finishes on magnesium parts help with corrosion protection, wear resistance, electrical insulation, and cosmetic appeal. The most common post-process finishes include: painting, e-coat, powder coat, electroless nickel, chrome, tagnite, keronite, anomag, urethanes, and UV coating.

These finishes drastically improve the cosmetics of magnesium parts and need to be applied by another vendor besides Proto Labs, which currently does not offer post-process finishing.

Please note note that higher polish finishes require additional time, a consideration to factor in if a very short lead time is required. It may be worth a less labor-intensive mold finish if you need parts within a few days and cosmetic appearance isn't a major issue. If you have any questions or concerns about plastic, LSR, or metal surface finishes, our CSEs can help guide you in the right direction. Please contact them at customerservice@protolabs.com or 877.479.3680 as early as possible to avoid any delays in production. For more information on surface finishes or to receive a quote, please visit protolabs.com.

Published December 2015

Rate this article

View our terms of use and privacy policy